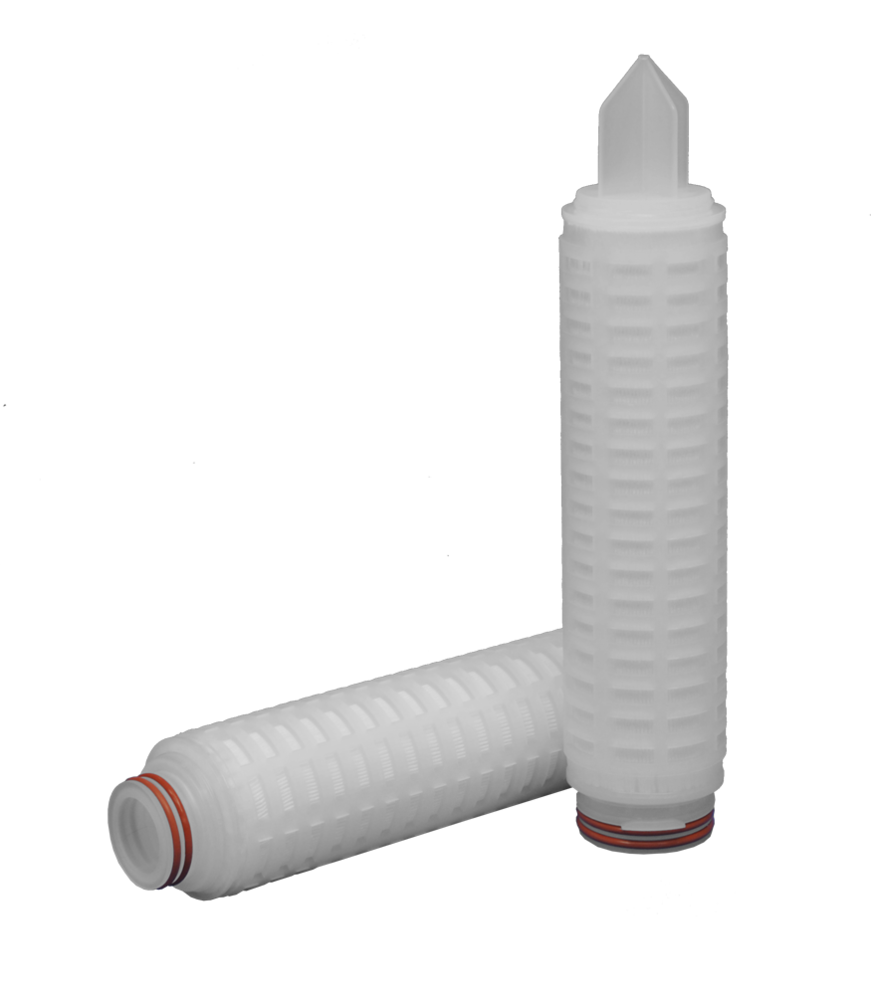

BPPF Series

The reinforced outer cage and center core enable to withstand harsh operating conditions, for example, hot water sanitization, which is typically used in food and beverage industry.

BPPF can significantly reduce numbers of yeasts and spoilage organisms from beverage products to provide microbial stabilization.

RoHS, FDA, Halal Certificated

Materials of Construction

Filter Media: Polypropylene

Hardware: Polypropylene

Sealing: Thermal Bond

Support Material: Polypropylene

End Cap Material: Polypropylene, Polysulfone Insert

Gaskets/ O-rings: Silicone

Operating Conditions

Maximum Operating Pressure: 75 psid (5.1 bar) @ 68°F (20°C)

40 psid (2.8 bar) @ 150°F (65°C)

Maximum Operating Temperature: 180°F (82°C), CIP 220°F (105°C)

Recommended Change Out Differential Pressure: 35psid (2.4 bar)

Sanitization & Sterilization: Hot Water @ 90°C for 30 min.

RoHS, FDA, Halal Certificated

Flow rate is per 10" cartridge. For liquids other than water, multiply the pressure drop by the fluid viscosity in centipoises.

Dimensions

Outside Diameter: 2.8" (71mm)

Lengths: 10", 20", 30", 40"

End Configuration

DOE

= Double open end

Code 3 = 222 / flat

Code 8 = 222 / Fin

Code 7 = 226 / Fin, Bayonet

Retention Ratings

0.2, 0.5, 0.6, 1.2, 2.5, 5, 10, 20, 30 µm Absolute